What are the special features of miniPelleter

Smart solutions taken from industrial pellet mills in the miniPelleter

Durable main shaft for stable power transmission during operation.

Safety locking levers provide a firm grip for stable assembly.

It reduces the downtime to the absolute minimum.

Adjustable scrapers precisely direct material under rollers.

Pellet mill designed and made for longevity

Components treated for high durability and corrosion resistance, ensuring long-lasting performance in demanding industrial environments.

We use reinforced bearings, including 33210 roller and 29416-E1 thrust models, ensuring high stability and a long operational lifespan under heavy loads.

All critical parts, including the flat die and rollers, are manufactured using precise CNC machining from high-grade alloy steel to guarantee a perfect fit and peak efficiency.

Every machine is expertly assembled at our facility in Poland, adhering to strict ISO 9001 quality standards and European CE safety requirements.

Why steam must go away from pelleting chamber?

During the pelletizing process, significant amounts of excess steam and hot air are generated within the pelleting chamber. This phenomenon occurs due to the high temperatures and pressures required to compress raw materials into solid pellets.

Exhaust pipe

Every miniPelleter is equipped with a specialized exhaust outlet located on the upper body of the machine. Here begins steams's way outside the pelleting process.

Mandatory aspirationn

To maintain stable production and machine longevity, all excess steam must be actively removed from the pelleting chamber using an industrial fan or just gravity.

Workplace safety HSE

Steam and hot air must be safely directed outside the device and the production room. This prevents moisture buildup and ensures a safe breathing environment for operators.

Moisture reduction

Efficient steam removal system significantly reduces the moisture level from feedstock in the pelleting chamber. This stage makes easier cooling and drying process in the cooler of any kind.

What is the Service Factor in pellet mill's drive?

The Service Factor represents a component's ability to handle loads beyond its rated capacity. For an industrial machine, it is the ratio between the maximum strength of the drive system and the actual power required for standard operation

The higher the Service Factor the stronger the pellet mill.

"Over-Engineered" for Reliability

The miniPelleter is designed with components that are intentionally oversized. This means that the massive shafts, heavy frame, and reinforced die housings are built to withstand significantly higher stresses than they encounter during routine pelletizing.

Drive System Resilience

-

Gearbox Selection: The gearboxes are specifically chosen for their durability under medium to heavy industrial loads. A high service factor in the gearbox prevents catastrophic failure when a raw material unexpectedly changes density or moisture, causing a sudden spike in resistance.

-

Motor Protection: By pairing robust 15 kW to 30 kW motors with high-quality starting systems (like SoftStart), the machine manages power surges efficiently, reducing mechanical wear on the internal gears.

Business Benefits of a High Service Factor

For a business owner, a high Service Factor is not just a technical spec—it is a financial safeguard:

-

Minimized Downtime: Components with a high SF are less likely to break under stress, ensuring your production remains continuous even when processing challenging materials like oak or straw.

-

Longer Equipment Lifespan: Machines that operate within their safety margins wear out much slower, leading to lower maintenance costs over time.

-

Higher Resale Value: Because the miniPelleter is built to industrial standards rather than hobbyist ones, it maintains a high market value for years.

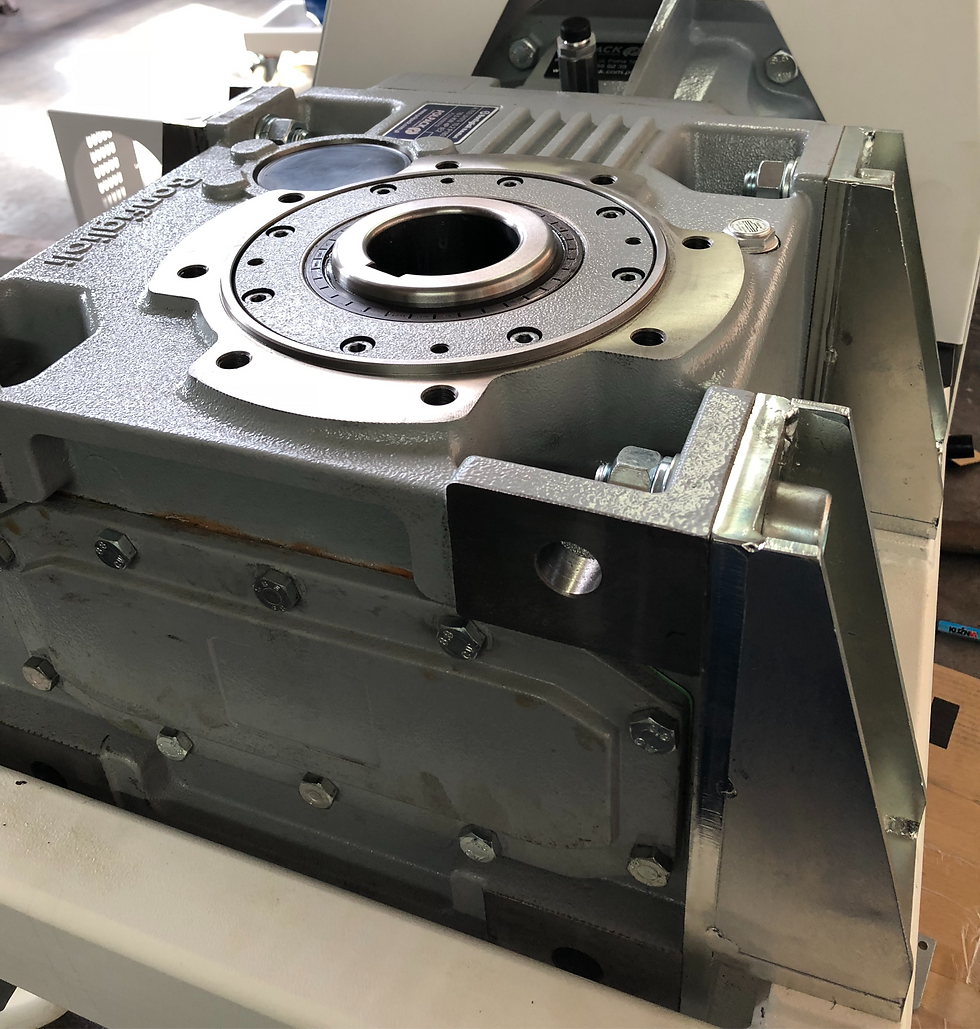

Drive & Gearbox System Specifications

The miniPelleter series utilizes robust and reliable drive systems designed for industrial operational demands.

Below are the specific details for the available configurations.

SF: 2.6

miniPelleter 22

This model features a direct gear drive system for efficient power transmission.

-

Main Motor Power: 22 kW

-

Gearbox Type: High-efficiency helical-bevel gear unit.

-

Starting System:

-

Standard: Star-Delta starter.

-

Optional: Soft-start or SoftStarter for smooth acceleration.

-

-

Permissible Load: Maximum operating current is 34 Amperes.

-

Lubrication & Maintenance:

-

Oil Type: Synthetic Industrial Gear Oil (e.g., Shell Omala S4WE 320).

-

Oil Capacity: Approximately 9 liters.

-

First Oil Change: Mandatory after the first 300 hours of operation.

-

Subsequent Changes: Recommended every 5,000 – 6,000 operating hours or once per year, whichever comes first.

-

Operator Safety Guard: The Hopper Safety Grid

The miniPelleter features a robust mechanical protection system installed directly within the intake hopper. This safety grid (mesh) acts as a critical physical barrier between the operator and the machine's internal moving parts.

Key Safety Features:

-

Anti-Reach-In Protection: The "open-work" design is engineered to allow the free flow of raw material (biomass or feed) while physically preventing hands or arms from reaching the dangerous rotating agitator shaft and mixing paddles.

-

Injury Prevention: This passive safety device is the first line of defense against severe mechanical injuries, eliminating the risk of contact with the crushing and rotating zones during operation.

-

Integrated Design: The grid is securely mounted inside the hopper, ensuring it cannot be easily bypassed during standard operation, while still allowing for visual inspection of the material flow.

This grid often works in tandem with the magnetic separator, ensuring that while operators are protected, metal contaminants are also caught before entering the pelleting chamber.

Safety & Protection Features for miniPelleter

The drive system is engineered with comprehensive safety measures to protect the machine and ensure long service life.

-

Overload Protection: An optional electronic sensor automatically shuts down the machine if operation exceeds permissible amperage limits for an extended period.

-

Temperature Monitoring (Optional): Sensors can be installed to monitor the temperature of critical components like the thrust bearing or gearbox, shutting down the drive in case of overheating.

-

Required Maintenance: Regular cleaning of the motor and drive chamber (minimum once a week) using compressed air is mandatory to prevent dust accumulation and eliminate fire hazards.

Slowly > Fast > Faster

What looks the feedstock dozing like in small pellet mill like miniPelleter?

Smart Feeding & Protection System

The miniPelleter does not rely on gravity alone. We have engineered an active Material Dispensing System designed to handle difficult, low-density biomass (like straw or sawdust) that typically bridges or clogs in standard hoppers.

1. Active Anti-Bridging Agitator

As seen in our operational photos, the hopper features a robust, rotating agitator shaft equipped with mixing paddles. This mechanism continuously stirs the raw material directly above the compression chamber.

-

Benefit: It prevents "hanging" or bridging of fibrous materials (straw, hay, sawdust), ensuring a constant, uniform flow into the pelleting die without manual intervention.

2. Integrated Magnetic Separator

Hidden beneath the mixing arms is a critical line of defense: the Magnetic Separator. Before the material enters the die to be compressed, it passes over powerful magnets integrated into the distribution plate.

-

Benefit: This system captures ferrous contaminants (nails, wire, screws) that could be hidden in your biomass, protecting the expensive die and rollers from catastrophic mechanical damage.

3. Uniform Distribution

The rotating assembly ensures that the raw material is spread evenly across the entire surface of the die.

-

Benefit: This guarantees equal wear on the rollers and bearings, maximizing the lifespan of your consumables and ensuring consistent pellet density.

SF 2.6

We don't build our machines to just 'get the job done.'

We engineer them with a high Service Factor

to ensure they survive the toughest conditions,

the most abrasive materials, and the longest shifts.

When you buy a miniPelleter, you are

buying a machine designed to handle

more than you will ever ask of it."